Deck board spacing refers to the gap between the sides of the deck boards and between the ends of the deck boards. If you’re DIYing your build, it’s important to understand the optimal spacing between deck boards for your chosen deck material.

How Much Space Between Deck Boards?

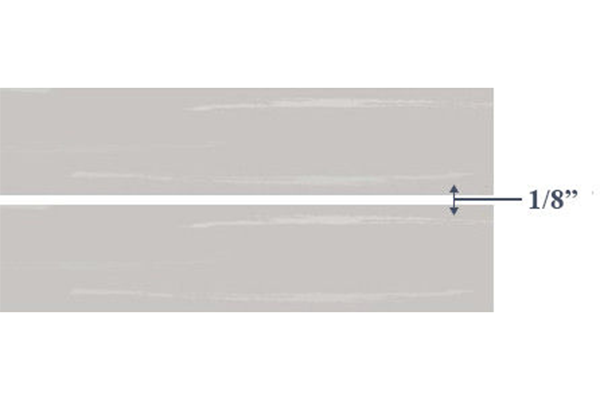

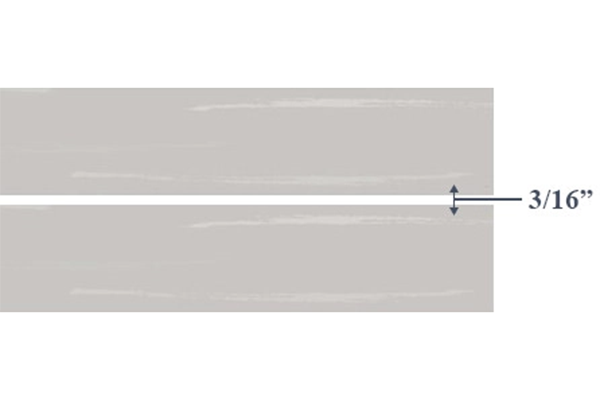

Side-to-side spacing: Typically 1/8”- 1/4″, depending on deck material and fastener type

End-to-end spacing: Depends on decking material

Why Proper Deck Board Spacing Is Important

✓ It allows enough space for the deck boards to expand/contract without buckling.

✓ It provides space for water drainage and airflow.

✓ Helps avoid moisture build-up which can cause mold and mildew.

Expansion & Contraction of Common Deck Materials

Recommendations for spacing between deck boards are not universal — they vary between decking materials due to how different materials expand and contract.

Expansion & Contraction by Material

The most common types of decking material expand and contract in different directions:

✓ Traditional wood expands along its width.

✓ Capped polymer and capped composite decking expands along its length.

Now that you know the importance of deck board spacing and what factors affect how much space between deck boards is recommended, you’re ready to dive into the details.

NEED THE 411 ON ALL THINGS DECK BOARDS?

Get the insight you need on everything you need, from types of composite decking to budgeting your project.

EXPLORE THE DECKING SERIES

Side-To-Side Deck Board Spacing

Side-to-side spacing refers to the gap between the length of the boards.

Side-to-Side Spacing With Traditional Wood

Traditional wood decking is typically installed with a 1/8” gap, as long as you install the boards after they have dried out and acclimated to your local climate. If installing freshly treated wood, install it tight (no gap) to allow for the shrinkage.

To acclimate your wood boards, let them sit in a dry area for one to two weeks before installing them.

IMPORTANT

Always refer to the installation guidelines for your chosen deck material before breaking ground on your project. VIEW INSTALL GUIDES

Side-to-Side Spacing for TimberTech Decking

TimberTech capped polymer and capped composite decking will not shrink side-to-side at all after installation, so it’s essential to get the correct spacing right at the time of install.

Factors That Affect TimberTech Decking Side-to-Side Spacing

- The decking line you choose

- The type of fastener you choose

The decking line and board profile and shoulder type you choose will influence which fastener options you’ll be able to use.

Side-to-Side Spacing Recommendations by TimberTech Decking Line

The decking line and board profile and shoulder type you choose will influence which fastener options you’ll be able to use.

What Is Board Profile & Shoulder Type?

The board profile has to do with how the underside of the board looks. There are two board profile options:

✓ Full profile (pictured)

✓ Scalloped

The board shoulder type has to do with how the sides of the board look. There are two shoulder options:

✓ Square shoulder

✓ Grooved (also pictured)

Side-to-Side Spacing Recommendations by TimberTech Decking Line

TimberTech Capped Polymer Decking

TimberTech AZEK® capped polymer decking spacing requirement:

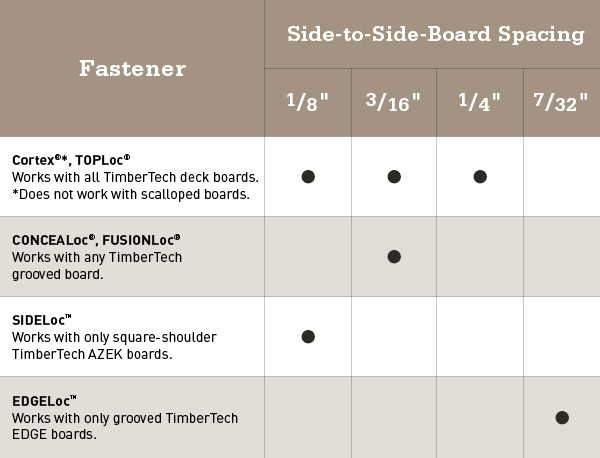

A minimum of 1/8” to 1/4” side-to-side spacing between the boards, depending on which fastener you use.

TimberTech Capped Composite Decking

TimberTech PRO® and TimberTech EDGE® capped composite decking spacing requirement:

A minimum of 1/8” to a maximum of 7/32” side-to-side spacing, depending on which fastener you use.

Side-to-Side Spacing Recommendations by Fastener Type

Once you’ve chosen your decking line and board type, you’re ready to choose your fastener type which will help inform how much space between deck boards you’ll need. Fasteners can be either top-down fasteners or hidden clip fasteners, and certain fasteners are only compatible with certain decking lines, board profiles, and shoulder types.

NEED TO CALCULATE HOW MUCH DECKING YOU’LL NEED?

The side-to-side deck board spacing gap you go with is essential in calculating how much decking you’ll need for your build. LEARN MORE

Curated Deck Board & Fastener Pairings

Want a cheat-sheet for which deck boards and fasteners go together? Check out these curated pairings for a winning combination.

TimberTech AZEK With Cortex® Hidden Fasteners

Cortex top-down fasteners are hidden with plugs made of TimberTech deck boards for a refined, seamless deck surface.

RATHER WORK WITH A CONTRACTOR?

We have your back. Partner with a TimberTech-registered contractor and get your job done right. FIND A CONTRACTOR

End-to-End Deck Board Spacing

End-to-end spacing between deck boards refers to the spacing — if any — between two board ends that meet, called a butt joint.

Because traditional wood primarily expands along its width and there is little risk of buckling at butt joints, it does not require a gap between the ends of the boards.

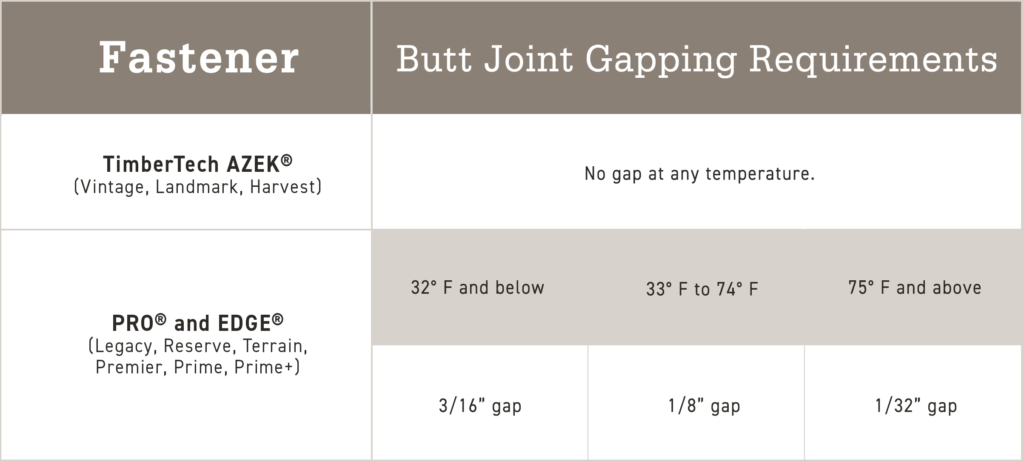

As you’ll recall, TimberTech capped polymer and capped composite decking expands and contracts along its length, so proper end-to-end spacing is critical. The end-to-end spacing recommendations depend on which TimberTech product line you choose.

End-to-End Spacing Recommendations by TimberTech Decking Lines

TimberTech Capped Polymer Decking

TimberTech AZEK decking does not require an end-to-end spacing gap, just like traditional wood. This is because of its unique material makeup, which won’t buckle due to expansion with a tight install.*

TimberTech Capped Composite Decking

TimberTech PRO and TimberTech EDGE deck boards do have specific end-to-end spacing requirements.

How much space deck boards will need depends on the outdoor temperature at the time of installation.

*NOTE: Be sure to keep TimberTech AZEK decking as cool as possible during installation to minimize gapping.

Water Drainage & Airflow

Besides accommodating expansion and contraction of the boards, spacing between deck boards also helps with water drainage and airflow — which is especially important for traditional wood decks.

Drainage & Airflow Concerns for Wood Decks

For a traditional wood deck, insufficient gapping can increase the chance of moisture damage to the deck surface and substructure, which can cause issues like:

✓ Mold, mildew, and/or rot

✓ Cracking, splitting, cupping, or warping

✓ Frequent deck board replacement

Drainage & Airflow Concerns for Composite Decks

For a TimberTech deck, there’s little concern of moisture damage to the surface of the deck. However, insufficient gapping can cause standing water on your deck surface — while the water won’t hurt your deck boards, it could make for an unsafe walking surface.

Beyond Deck Board Spacing: Explore More DIY Resources

Now that you have a better understanding of side and end spacing between deck boards, you’re ready to explore more resources to complete a successful DIY build you can be proud of.

Explore our Deck Building Resource Center for more DIY installation insight with easy-to-follow videos, step-by-step installation guides, and more helpful considerations to guide your build.