If you’re in the market for a deck, you’ve likely heard of composite decking — and at least some discussion of board “capping.” But what exactly is a deck board “core” and “cap”? And why is TimberTech capped composite decking a superior choice for your home in terms of increased long-term value, enduring beauty, and minimal upkeep?

Because we believe Better Tech, Better Deck.™

NEED THE 411 ON ALL THINGS DECK BOARDS?

Get the insight you need on everything you need, from types of composite decking to budgeting your project.

EXPLORE THE DECKING SERIES

A Brief History of Capped Composite Decking

For many years, pressure-treated wood was the primary deck material choice for residential decks. Even today, many homeowners think “wood” when they hear mention of decking – but even pressure-treated lumber comes with issues.

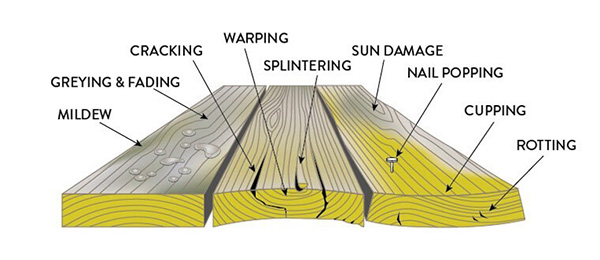

Why Wood Can’t Cut It

All wood – whether highly sought-after hardwoods like Ipe or common pressure-treated lumbers like cedar or pine – are made of organic material. That means they’re made of the literal food that mold and mildew like to eat – and without a protective cap, mold and mildew will get in. The result? Issues to the beauty and structural integrity like you see here.

As part of the market’s search for a wood alternative, a new product was introduced in the 1990s: composite decking. This first-generation building material provided homeowners with a durable decking alternative to traditional lumber.

First-Gen Composite Decking: Less Organic Material Than Wood, But No Cap

Composite decking became extremely popular over the years – but first-generation composite products had their issues. The main culprit? No protective capping.

Despite claims of increased durability, early composite deck boards faded or lost structural integrity faster than was desired.

The ‘What’

Pictured: Side view of a grooved composite deck board. A board with no capping leaves its composite core exposed to the elements.

Boards were made of an engineered blend of plastics and wood fibers. Early boards did not include a protective polymer layer around the board core, now referred to as a “cap.”

The ‘So What?’

Pictured: Pine wood after being exposed to moisture via sponge test. Composite decking had less organic material for moisture to impact.

Synthetic materials fortified wood (shown above) against many of the issues that plague traditional lumber: invasion by moisture, fading, staining, cracking, and so on.

Next Up: Capped Composite Innovation

Leveraging a process called coextrusion, we looked at the potentially vulnerable composite cores on the market – and improved them.

TimberTech Capped Composite Decking 101

We make the CORE of our capped composite deck boards from a mix of post-consumer plastics and recycled lumber.

The CAP is made from a high-performance proprietary polymer blend. This protects the boards against invasion by moisture, the fading effects of UV rays, and other factors that contribute to erosion.

Composite Deck Board Core

- Sustainable: 100% of the plastic and wood used in the cores of TimberTech PRO and EDGE boards is recycled.

- Innovative: We take plastics that would otherwise be thrown away – think scrap material and post-consumer products like shampoo bottles and plastic wrap – and transform them into high-performance composite deck boards.

Composite Deck Board Cap

- No same mold, same mold: TimberTech capped composite boards resist mold and mildew growth by protecting against moisture.

- Sustainable: Our composite deck boards overall (core plus cap) are made from up to 80% recycled material.

- Forget about fading: Coextruded caps don’t involve a stain – the color is a part of the cap. That means your deck looks as great on day 1,000 as on day 1.

NOT SURE WHICH DECKING LINE IS RIGHT FOR YOU?

Compare our TimberTech AZEK, PRO, and EDGE to find the right material for your build. COMPARE DECKING

What’s more, unlike first-generation composite decking (and of course, wood), TimberTech capped composite decking delivers major benefits in terms of increased long-term value, enduring beauty, and minimal upkeep.

Increased Long-Term Value

Capped composite decking foregoes the costly maintenance and replacement associated with wood – and elevates your home’s overall design. A TimberTech composite deck benefits you in two ways: long-term value earned by the investment, and increased resale value for your home.

Enduring Beauty

Industry-leading performance backed by competitive warranties, including a 30-Year Fade & Stain Warranty for TimberTech PRO decking. Your deck captures all the beauty of real wood, but then stays beautiful, rain or shine.

Minimal Upkeep

Want a high-style, low-maintenance outdoor living space? Then you want capped composite decking. TimberTech decking doesn’t require the sanding, staining, or re-sealing that pressure-treated wood decks demand – just a little TimberTech DeckCleaner™* and rinse.

*Note: TimberTech DeckCleaner™ is formulated, field tested, and approved for cleaning TimberTech AZEK® decking or porch, TimberTech PRO® decking, TimberTech EDGE® decking, and TimberTech composite railing. On average, one gallon diluted with one part cleaner to three parts water will clean approximately 1,000 square feet of surface area. As always, refer to the Care & Cleaning Guide for your specific decking product before beginning.

Capped Composite Decking FAQs

It’s important to know how far capped composite decking has come, and just how composite decking can do more for your outdoor living space than wood can. (Check, and check).

But there’s a final important question you might be asking: Do I lose any of the benefits I associate with wood by choosing composite decking instead?

The short answer: Nope.

What Is the Cheapest Capped Composite Decking?

Unlike some other additions to your home, calculating deck cost isn’t quite as simple as cost-per-square-foot. A host of factors – including deck size, labor costs, and fasteners – will influence the overall cost to build a deck.

It’s also important to really consider what is meant by “cheapest.” A lower initial cost for a deck material – whether traditional wood or a capped composite decking line – doesn’t necessarily mean the lowest overall expense (because you may pay more over time in upkeep). Look for the best durable deck material worth the investment.

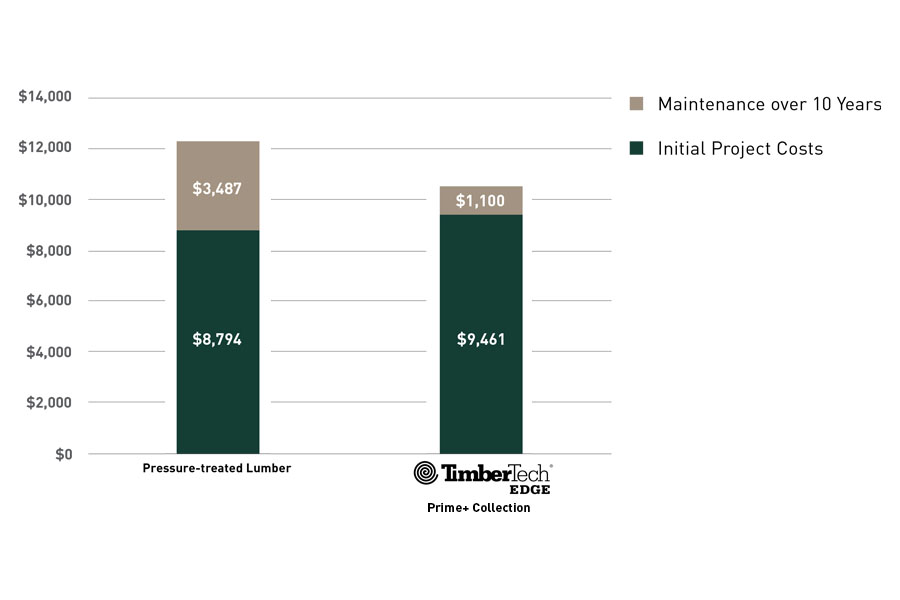

Costs Over 10 Years: Pressure-Treated Lumber vs TimberTech EDGE

The estimated average cost of capped composite deck boards and pressure-treated lumber decking costs are based on the national average for a 16’ x 20’ deck. Meant for visual representation only. Actual costs may vary.

When looking at the differences in cost between pressure-treated lumber and TimberTech EDGE, the upfront costs are similar, with TimberTech EDGE coming in slightly higher.

However, maintenance costs over a 10-year period, show that pressure-treated lumber costs over 3x more than TimberTech EDGE.

TimberTech EDGE is an accessible, attractive capped composite option – and serves as a value-rich transition from traditional lumber.

Can Composite Decking Go Over Concrete?

Yes – and if you’re already making the choice to transform your patio, it’s likely cracked or otherwise unsightly, and you likely aren’t a big fan of maintenance and upkeep.

Why pay into a final product that quickly starts deteriorating, like a traditional wood deck, instead of one that increases the resale value of your home?

Is Composite Decking as Attractive as Wood?

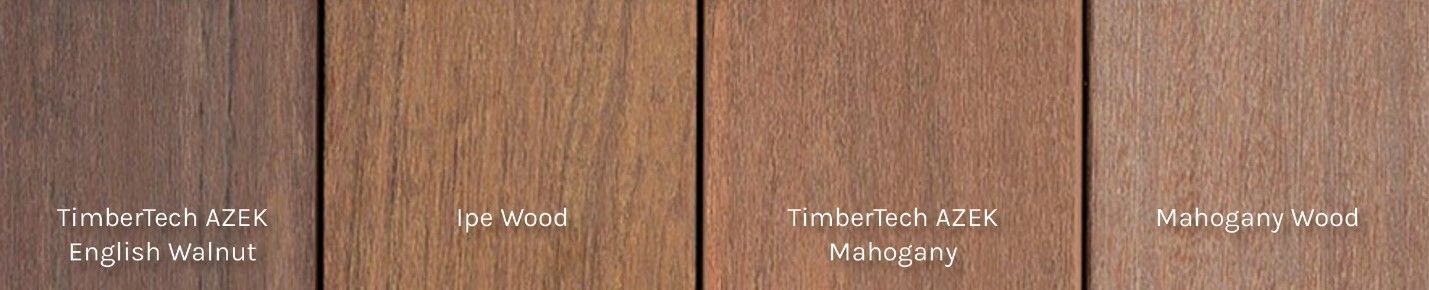

Thanks to the shaky first impression made by first-generation composite decking, there is a myth that composite deck boards can’t capture the nuanced beauty of real wood deck boards. But that’s a ’90s trend we’re proud to have left behind.

Our innovative materials technology means our boards are defined by nature-inspired beauty: realistic grain patterns, options for color blending, and aesthetics lifted from reclaimed hardwoods.

Myth: busted.

Explore Capped Composite Decking From TimberTech

Now you know that TimberTech capped composite decking innovates far beyond first-generation composite deck boards – and that it delivers benefits wood just can’t compete with.

Speaking of competition, nothing beats seeing the real wood-look and realistic grain patterns right in front of you – so, go ahead. Order up to four free samples delivered right to your door and experience the TimberTech difference for yourself.